For some of the turnouts on the passenger station side of the layout are situated close together similarly to what is in the yard. But these are normal vertical mounted controls so getting them close together requires using "remote" controls.

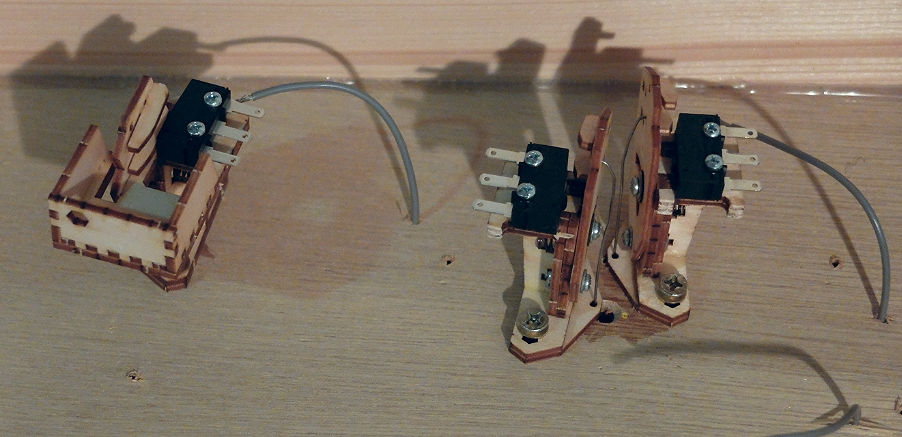

The difference between the normal vertical mount and a "remote" vertical mount is visible here. Essentially, the cable support box in the normal configuration is eliminated during the assembly. Unfortunately, I failed to build enough of the controls in that configuration so I had to create these two modified units by clipping off the box - this explains why in the unit on the right is visible some left over material from the removed box :o).

Also, because these two units are so close together I had to slightly rotate the units away from each other so as to not have interference between the moving portions of the controls. This wouldn't be an issue with larger scales as the spacing would alleviate the potential overlap. I found that the slight rotation didn't significantly impact the motion out at the points and it seems to work just fine.

I did however discover that while I thought that the motion of the control plate of the turnout control seemed smooth enough prior to installation, following installation on the module the control seemed much tighter and was close to being locked up. I removed the moving portion of the control and found that the channel in which the ball bearing moved has sharp vertically edges and I found it necessary to take a blade to carve away some of the material in order to cut down the edges a bit to reduce the resistance of the spring-loaded bearing to depress and move within the channel. After reassembling the units, the controls now work fairly smoothly.